Tydens die granulasieproses van 'n voerkorrelmasjien is daar individuele voerkorrels of individuele voerkorrels met verskillende kleure, algemeen bekend as "blomvoer". Hierdie situasie kom algemeen voor in die produksie van watervoer, hoofsaaklik gemanifesteer as die kleur van individuele deeltjies wat uit die ringmatrys geëkstrueer word, donkerder of ligter is as ander normale deeltjies, of die oppervlakkleur van individuele deeltjies wat inkonsekwent is, wat daardeur die voorkomskwaliteit van die hele bondel voer beïnvloed.

Die hoofredes vir hierdie verskynsel is soos volg:

a)Die samestelling van voergrondstowwe is te kompleks, met te veel tipes grondstowwe, ongelyke vermenging en inkonsekwente voginhoud van die poeier voor verwerking van voerdeeltjies.

b)Die voginhoud van die grondstowwe wat vir granulering gebruik word, is inkonsekwent. In die produksieproses van watervoedsel is dit dikwels nodig om 'n klein hoeveelheid water by die menger te voeg om te vergoed vir die verlies aan water in die grondstowwe na ultrafyn druk. Nadat dit gemeng is, word dit dan na die opknapper gestuur vir tempering. Sommige voervervaardigers gebruik 'n té eenvoudige proses om voer te maak - plaas die materiaal wat vir die formule benodig word, direk in die menger en voeg genoeg water by, in plaas daarvan om 'n gedetailleerde en stadige byvoegproses volgens professionele vereistes uit te voer. Daarom vind hulle dit moeilik om 'n gebalanseerde verspreiding van voerbestanddele in terme van wateroplosbaarheid te verseker. Wanneer ons hierdie gemengde bestanddele vir kondisioneringsbehandeling gebruik, sal ons vind dat as gevolg van die doeltreffendheid van die opknapper, die voginhoud nie vinnig eweredig versprei kan word nie. Daarom verskil die volwassenheid van die verwerkte voerprodukte onder stoomwerking baie tussen verskillende dele, en die kleurhiërargie na granulering word nie duidelik genoeg nie.

c)Daar is herwonne materiale met herhaalde granulering in die granulasiebak. Die korrelmateriaal na granulering kan eers in die finale produk verander word nadat dit afgekoel en gesif is. Die gesifte fyn poeier of klein deeltjiemateriaal kom dikwels in die produksieproses vir hergranulering, gewoonlik in 'n menger of wag vir granulasiesilo. As gevolg van die feit dat hierdie tipe terugvoermateriaal hergekondisioneer en gegranuleer word, kan dit soms "blommateriaal" vir sekere voerformules produseer as dit oneweredig met ander hulpmateriale gemeng word of met terugvoermasjien klein deeltjie materiaal gemeng word.

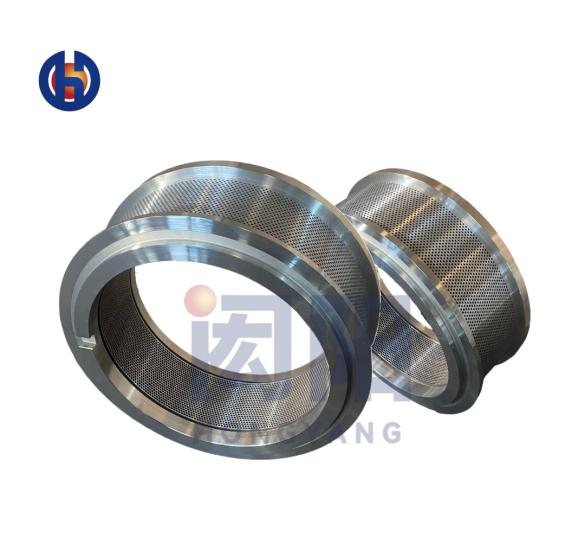

d)Die gladheid van die binnewand van die ring-matrysopening is inkonsekwent. As gevolg van inkonsekwente oppervlakafwerking van die matrysgat, is die weerstand en ekstrusiedruk wat die voorwerp tydens ekstrusie ervaar verskil, wat lei tot inkonsekwente kleurveranderinge. Daarbenewens het sommige ringmatryse brame op die klein gaatjie-wande, wat die oppervlak van die deeltjies tydens ekstrusie kan krap, wat lei tot verskillende oppervlakkleure vir individuele deeltjies.

Die verbeteringsmetodes vir die vier redes vir die vervaardiging van "blommateriaal" wat hierbo gelys is, is reeds baie duidelik, wat hoofsaaklik die vermengingsuniformiteit van elke komponent in die formule en die menguniformiteit van die bygevoegde water beheer; Die verbetering van die blus- en temperprestasie kan kleurveranderinge verminder; Beheer die terugvoermasjienmateriaal. Vir formules wat geneig is om "blommateriaal" te produseer, probeer om nie die terugvoermasjienmateriaal direk te granuleer nie. Die terugvoermasjienmateriaal moet met die grondstof gemeng word en weer fyngemaak word; Gebruik ringmatryse van hoë gehalte om die gladheid van die matrysgate te beheer, en indien nodig, slyp die ringmatrysgate voor gebruik.

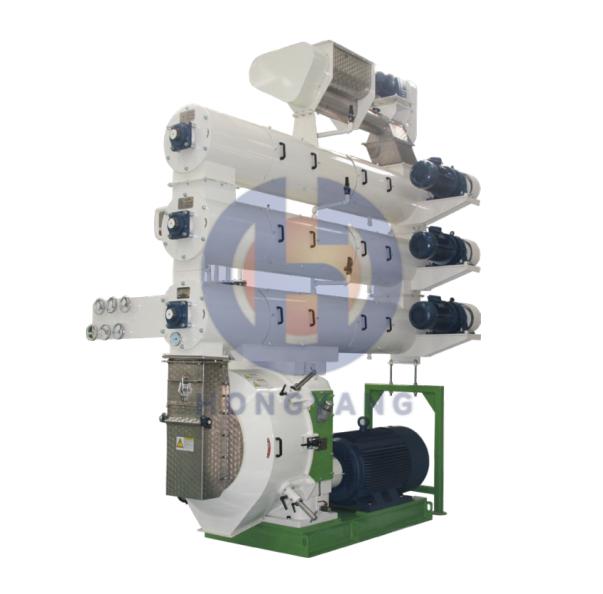

Dit word aanbeveel om 'n twee-laag dubbel-as differensiële conditioner en 'n twee-laag verlengde baadjie conditioner op te stel, met 'n blustyd van tot 60-120 sekondes en 'n blustemperatuur van meer as 100 ℃. Die blus is eenvormig en die werkverrigting is uitstekend. Die gebruik van meerpuntluginlaat verhoog die deursnee-area van die materiaal en stoom aansienlik, waardeur die volwassenheid van die materiaal verbeter word en die blus- en tempereffek verbeter; Die digitale instrumentpaneel en temperatuursensor kan die temperatuur van die kondisionering vertoon, wat dit maklik maak vir gebruikers om enige tyd te beheer.

Kontakinligting vir tegniese ondersteuning:

Whatsapp: +8618912316448

E-pos:hongyangringdie@outlook.com

Pos tyd: Jul-26-2023